Aerospace

Identification solutions for the the Aerospace Industry.

Custom parts marking and identification labels and nameplates, Barcoding, Fabricating, and MIL-STD-130 UID Labeling.

ISO 2001:2015 Quality Certified. ITAR Registered. AS9102 First Article Inspections, And always trusted quality you can depend on.

UID & Barcode Labels, Nameplates and Placards for Aerospace & Defense

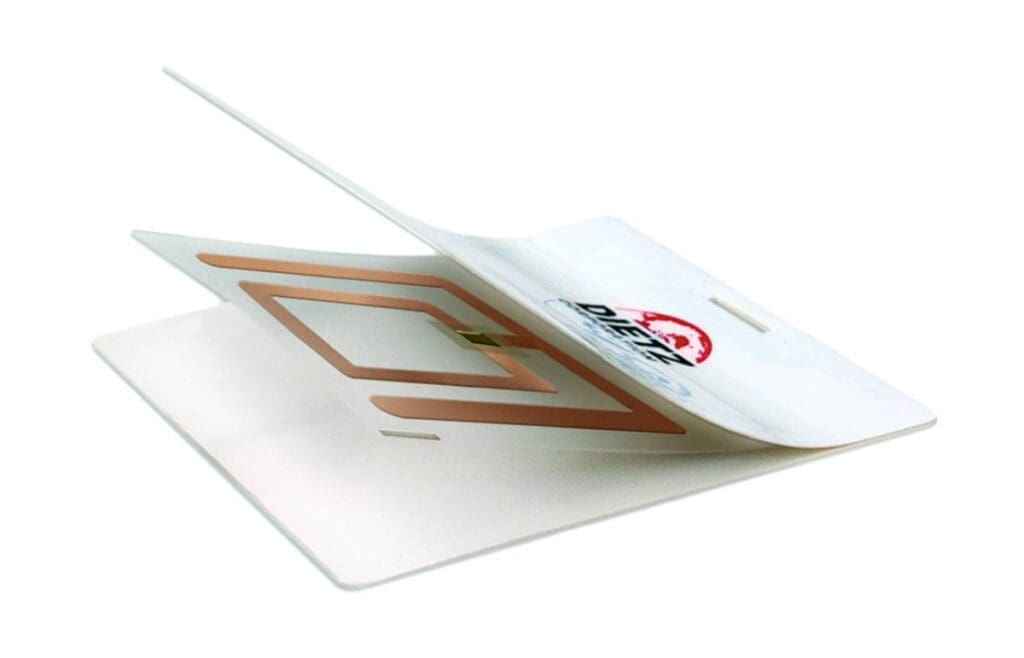

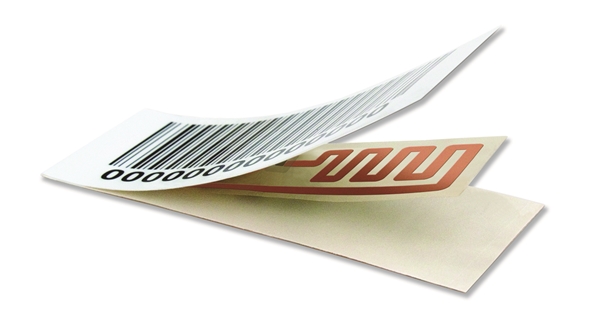

The Department of Defense (DOD) and aerospace & defense manufacturers trust Express for the most durable UID labels, barcode tags, and identification solutions.

Durable UID & barcode identification products withstand the demands of the aerospace & defense industry, including exposure to oil, grease, caustic chemicals, salt spray, moisture, UV radiation, extreme temperatures, multiple freeze-thaw cycles, abrasion, and other environmental challenges. All UID & barcode tags, labels, and nameplates are designed to last the life of aerospace and defense equipment, with data integrity and read-rates that do not degrade over time. UID, barcode, and data matrix technology allow you to track assets and collect data with confidence in the harshest conditions. All UID tags are guaranteed to comply with Department of Defense Mil-Std-130 and STANAG 2290.

Trust Express

- 30+ Years of Industry Experience

- Manufactured in the USA

- First Article Inspection & UID Verification Reports

- ISO 9001 Certified – AS9100 Compliant

- DFAR Compliant Material

- ITAR registered

Aerospace & Defense ID Solutions — UID & Barcode Labels, Nameplates and Placards

Aerospace & Defense Standards and Specifications

- AS9102 – This SAE Aerospace Standard (AS) establishes requirements for performing and documenting the First Article Inspection (FAI).

- MIL-STD-130N – This standard provides the item marking criteria for development of specificmarking requirements and methods for identification of items of military property produced, stocked, stored, and issued by or for the Department of Defense. This standard addresses criteria and data content for both free text and machine-readable information (MRI) applications of item identification marking.

- MIL-P-38477A(USAF) – This specification covers an adhesive-backed, pigmented or clear polyester plastic film for marking of aerospace interior and exterior surfaces.

- MIL-T-9906C – This specification for identification tape used for tubing markers covers the requirements for one type of printed, pressure-sensitive, non-corrosive identification tape, which shows different designs and used for identifying tubing lines on vehicles and aircraft. This tape shall withstand temperatures between the range from plus 325 to minus 290°F (plus 163 to minus 179°C) and shall be resistant to fuels, lubricating oils and hydraulic fluids.

- MIL-P-8793A(ASG) – This specification covers paint for use in the manufacture of decalcomanias intended for application on the exterior and the interior surfaces of aircraft and aeronautical equipment.

- MIL-STD-1247D – This standard establishes material labeling requirements for identification, function, subfunction, pressures, hazards and direction of flow for pipes, hoses and tube lines used in aircraft, missile, space systems, and support equipment. The use of colors, words and symbols to identify the functions of such items (to include approved abbreviations), and the dimensions of labeling items such as tags, tapes, and bands, are specifically prescribed.

MIL-STD-130 and STANAG 2290 UID / IUID Compliance

- Sub-surface aluminum, photo-imaged

- Laser-etched on black anodized aluminum

- Stainless Steel chemically etched and filled with a baked enamel

- Laser-etched on Tesa® polyacrylic film, with temperature resistance from -59F to +392F

- Durapoly™ polyester

- Metalized polyester

- Kapton, Surface printed black on white background with high temperature resistance

FEATURES

- 21 Point Inspection Every Order

- Every Barcode Validated for Accuracy

- Complimentary Certificate of Conformance

- ISO 9001 Certified

- Fastest Turnaround Times in Industry

- Streamlined Production

- 24 Hour Rush Expedite Available

- Clean Manufacturing

- Custom Design & Build

- Free Graphic Design Services

- Helpful Customer Service

- Unlimited Proofing & Revisions

- Driving Business Efficiency