Barcode Labels

Expert design assistance and numerous material and design options available to create exactly what you need.

Achieve flawless data capture with barcode labels engineered for maximum performance and unmatched durability in every environment, from office to factory and field.

Labels that perform under conditions of exposure to Solvents, Chemicals, UV Exposure, Abrasives, Extreme Heat, Sub-Zero Cold, Moisture and general harsh Industrial environments.

Every Express product is made in the USA under our ISO Certified quality program to ensure superior quality, rapid production cycles, and fast, dependable delivery.

With over 40 years of expertise, we produce labels with outstanding readability, long-lasting durability, and a total customer satisfaction guarantee on every barcode label order - your success is our priority.

Custom Barcode Labels

Data capture with barcodes works best with quality Barcode Labels that deliver outstanding readability. Yet many labels fail to provide reliable performance across diverse industrial environments, leading to costly delays and system disruptions. Common failures include:

- Barcode misreads due to poor printing or label material degradation

- Labels that fade, peel, or corrode in chemical-heavy environments

- Adhesive failures in challenging environments

- Incomplete serialization or non-compliant formatting

- Incompatibility with scanning hardware or data systems

Express Identification Products solves these these challenges with custom-engineered barcode labels designed for long-term durability and highest level read rates, delivering flawless performance in even the most demanding environments. Express provides:

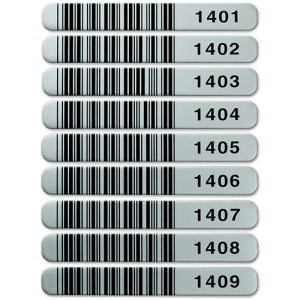

- 100% Sequence Integrity: No missing barcodes – and no data collection process disruptions.

- Exceptional Readability: All Express barcodes are verified compliant to ANSI and other applicable standards for contrast, modulation, element dimensionality and ultimately, readability. They are certified to conform to all relevant industry standards. Providing no misreads and quick and reliable data capture.

- Outstanding Durability: Barcode Labels that last decades in even the most challenging environments. Anodized aluminum with sub-surface image or a variety of other materials are available depending upon your needs. Choose Aluminum, Steel, Polycarbonate, Magnetic Vinyl or another high performance material.

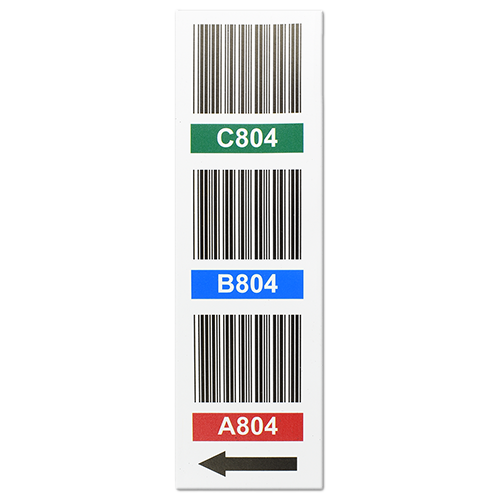

- Smart Customization: Any barcode symbology is supported: Code 39, QR Code, Data Matrix, 128, and more. Produced with serialized or any random data you may provide. Plus; color and logos or other graphic elements can be included in your design.

- Precision Engineering Throughout: From Data management and formatting, barcode layout, specialty adhesives and coatings, and precision fabrication processes to finish your labels. Every label is engineered to match your application and provide optimum scanning results.

- Certified Labels: Every order comes with our Certificate of Conformance.

Simple Ordering Process

Ordering is easy, collaborative, and tailored to your exact needs. Every barcode labeling project includes free digital proofs for your review and approval of layout and data. This ensures your designs align perfectly with your operational and compliance standards. We perform barcode verification on your products to guarantee scan accuracy and system compatibility.

Throughout the process, our Barcode engineers provide expert guidance on selecting the optimal materials, barcode symbology, adhesives or other mounting solutions. We ensure your labels meet your technical requirements, compliance needs, and field durability expectations – every time.

Technical Specifications

Our barcode labels are engineered for industrial environments where durability, readability, and system compatibility are essential. Designed to meet strict operational and compliance requirements, each label is custom-built with high-performance materials, precise barcoding, and flexible mounting options to ensure long-lasting identification in any application.

Material Options:

- Anodized aluminum (sub-surface image/photo-imaged)

- Stainless steel (laser-marked or chemically etched)

- Polycarbonate, polyester, and vinyl materials for less demanding applications

- Optional Teflon™ coating, polyester overlaminate, or ceramic coatings

Size & Shape:

- Custom sizes and shapes to fit any application

- Rectangle, circle, rounded corners, or fully custom die-cut

Barcoding & Serialization:

- Every barcode symbology is supported (Code 39, 128, Data Matrix, QR Code, etc.)

- Sequential, non-sequential, or batch coding

- Scannable, human-readable data options

Mounting Options:

- Premium 3M® industrial adhesives

- Pre-drilled holes for rivets, nails, screws, or wire ties

- Adhesive + mechanical combinations for added strength

Environmental Resistance (Aluminum example):

- UV stability for 20–30+ years outdoors

- Withstands chemicals, salt spray, solvents, and abrasion

- Performs in extreme temperature, moisture, and pressure conditions

Your Barcoding System may benefit from these other Express Solutions

Maximize the effectiveness, efficiency, and longevity of your labeling system by pairing your custom barcode labels with these complementary identification solutions. Each product is designed to support broader traceability, compliance, and operational visibility across industrial environments:

- Barcodes for Warehouse — A variety of labels for Rack and Shelf location identification in warehouses. Rack Labels, Long Range barcode labels, Floor Labels, Magnetic Barcodes and more.

- Asset Tags — Permanently mark tools, equipment, and infrastructure with rugged asset tags engineered for lifetime traceability and seamless integration with asset management systems.

- UID Labels — Meet stringent military and aerospace standards with UID-compliant barcode labels that deliver unique identification, high-scan accuracy, and durable performance in the harshest conditions.

If you’re unsure what product best supports your application, our experts are here to help you design a tailored labeling system that aligns with your operational, environmental, and compliance needs. Contact our Specialists today to build your ideal custom identification system.

Industries We Serve

Express barcode labels are trusted by leading organizations across high-stakes industries where reliable identification, flawless data capture, and rugged durability are essential for success.

- Aerospace & Defense — Ensure full traceability with serialized barcode labels, UID-compliant tags, and high-performance identification solutions for mission-critical components, tools, and assemblies.

- Oil & Gas — Durable barcode labels for identifying valves, pipes, pressure points, and field equipment in high-temperature, high-corrosion environments. Built to withstand UV exposure, chemicals, and offshore conditions. Perfect for LDAR (leak detection and repair) programs.

- Manufacturing & Industrial Processing — Track work-in-progress (WIP), manage batch production, and ensure compliance with custom barcode labels that integrate with MES, ERP, and process control systems.

- Warehousing & Logistics — Improve inventory accuracy, location scanning, and equipment tracking with warehouse barcode labels for racks, pallets, bins, and mobile assets. Designed for high-scan reliability and fast-paced distribution environments.

- Utilities & Energy — Label electric, water, and gas utility assets with lifetime-durable barcode solutions for meters, transformers, valves, and infrastructure components. Ideal for outdoor use and long-term traceability.

Why Choose Express Identification Products?

Choosing Express means partnering with a trusted industry leader who understands that barcode performance, durability, and compliance are essential. With decades of experience and a reputation for accuracy and precision, we deliver barcode labeling solutions engineered to perform exactly as needed, every time.

- Over 40 Years of Labeling Expertise – Since 1984, we’ve helped thousands of businesses across aerospace, energy, logistics, and manufacturing solve their toughest identification challenges with custom barcode label systems that last.

- ISO 9001:2015 Certified Manufacturing – Our U.S.-based production facility follows strict quality control standards to ensure consistent results. From material selection to final barcode output.

- Barcode Verification for 100% Scan Reliability – Every label is tested using ANSI/ISO grading systems to ensure perfect scan accuracy, even in high-speed or automated environments.

- Seamless Integration with ERP, WMS & Compliance Systems – Whether you’re tracking serialized assets, managing inventory, or meeting UID or regulatory standards, our labels are built to fit directly into your operational workflows.

- Complete Satisfaction Guarantee & Reliable Ongoing Support – We stand behind every barcode label we produce with a total satisfaction guarantee and ongoing support from our team of technical specialists.

At Express, we don’t just print barcodes — we engineer high-performance labeling solutions built for extreme environments, rigorous scan requirements, and long-term functionality.

Don’t wait for label failures to disrupt your operations—start with a free sample kit and experience Express Identification Products performance and durability firsthand.

- Aluminum Photo Imaged With Sub-surface Image. Thickness ranging from .003" through .125"

- Aluminum Laser Engraved Natural on Black Anodized Background

- Stainless Steel Laser Marked or Etched and Filled

- Retro-Reflective Long-Range Adhesive Backed or Hanging Placards

- Polyester Second-Surface Imaged

- Polycarbonate Second-Surface Image

- Metalized Polyester Surface Image

- Polyester – Surface Image Surface Imaged

- Tesa Laser engraved

- Kapton/Polymide Digitally Printed

- Ceramic Ceramic Coated Steel