Oil & Gas

LDAR Tags

Barcode Labels, LDAR Tags and Placards for the oil & gas industry

Labeling Solutions for Oil & Gas Industry

Identification products for petrochemical industry including barcode labels and maintenance tags, leak detection checkpoint tags, inventory stores identification, site access wayfinding signage and general asset tagging. Durable barcode labels, tags and placards suitable for any environment.

LDAR technicians and Oil & Gas companies worldwide trust Express when it comes to reliable identification solutions in the field.

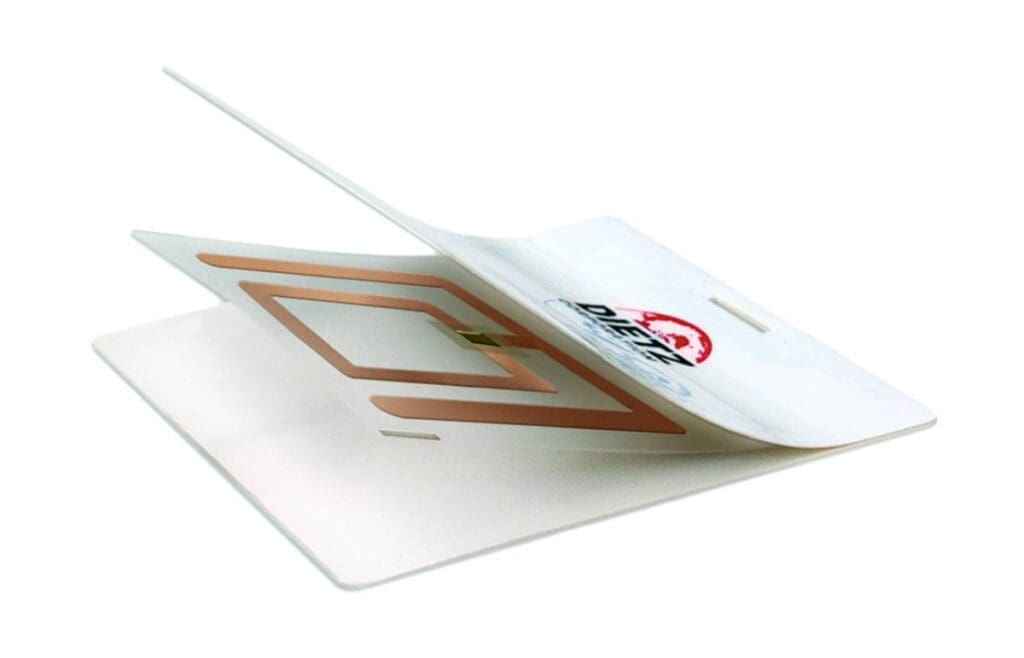

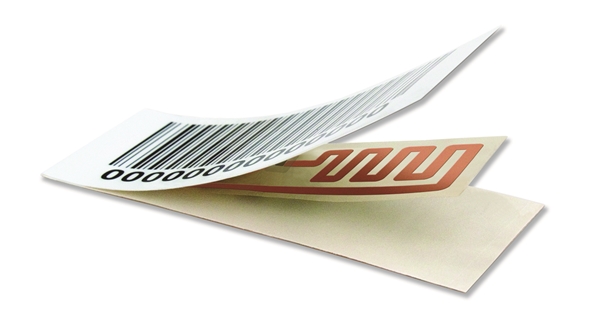

Durable barcode identification products are designed to withstand the toughest demands of the oil & gas industry, including exposure to oil, grease, caustic chemicals, salt spray, moisture, prolonged UV radiation, extreme temperatures, multiple freeze-thaw cycles, abrasion, and other environmental challenges. All barcode tags, labels, and nameplates are designed to last the life of oil rigs and equipment, with data integrity and read-rates that do not degrade over time. Barcode and data matrix technology allow you to track assets and collect data with confidence in the harshest oil field and oil rig conditions.

Barcode Identification Solutions

- Leak Detection and Repair (LDAR) Tags

- Valve & Pump Tags

- Maintenance Tags

- Instruction, Safety, and Warning Labels

Oil & Gas ID Solutions – Barcode Labels, LDAR Tags and Placards

About Leak Detection and Repair (LDAR)

The U.S. Environmental Protection Agency (EPA) established Leak detection and repair (LDAR) regulations and compliance programs in order to limit the amount of volitile organic compunds (VOCs) and volitile hazardous pollutants (VHAPs) emitted by leaking equipment such as valves, pumps and connectors in industries such as petroleum refining and chemical manufacturing. The EPA requires LDAR managers technicians to follow fundamental compliance and calibration procedures to keep LDAR programs in compliance.

LDAR Program Best Practices

At a minimum, a LDAR program should schedule inspections to ensure compliance, track work orders as soon as leaks are detected, and report such leaks to the appropriate environmental agency. These best practices are streamlined with the use of automatic data capture technology, such as barcode labels and tags.

- Leak Detection and Repair: A Best Practices Guide

- Air Emission Measurement Center (EMC) Test Methods

- Method 21: Volatile Organic Compound Leaks

- Inspection Manual: Federal Equipment Leak Regulations for the Chemical Manufacturing Industry

- EPA Compliance Monitoring Programs

- EPA Greenhouse Gas Reporting Program (GHGRP) – Subpart W – Petroleum and Natural Gas Systems

5 Components of an Effective LDAR Program

- Identifying Components

Every regulated component must have a unique identification number and an identified location. LDAR technicians should maintain an equipment log that tracks replacement parts, new equipment and equipment removed from service. ID numbers should be clearly marked on all equipment and must remain readable for the life of the equipment.

- Leak Definition

Leaks are defined as a measured concentration of a compound exceeding a standard, acceptable threshold as defined by the appropriate regulatory authority. Leaks are measured in parts per million (ppm), and different federal and state regulations have different acceptable thresholds. In some cases, multiple federal and/or state regulations may apply. In such cases, the EPA recommends defining leaks at the lowest minimally accepted threshold among the applicable regulations.

- Monitoring Components

EPA Reference Method 21 is the primary method used to monitor equipment for purposes of leak detection. Under Method 21, LDAR technicians use a portable detection instrument to evaluate emissions on a weekly, monthly, quarterly, or annual basis.

- Repairing Components

Regulatory guidelines determine when a leak must be repaired after detection. Typically, an LDAR technician must attempt to repair a leak within 5 days of detection. If the first attempt to repair is unsuccessful, the LDAR technician must make a second attempt to repair within 15 days. Asset management systems and LDAR tags can help technicians document such repair attempts, monitor equipment life cycle and conduct preventative maintenance.

- Recordkeeping

Federal and state LDAR regulations have strict documentation standards and require complete and accurate records on every regulated part. An asset management system that incorporates automatic identification and data capture through the use of LDAR tags can make the record keeping and compliance process significantly faster, more accurate and less expensive.

LDAR Regulations and Programs

United States – Federal

- 40 CFR Part 60, Subpart VV – Standards of Performance for Equipment Leaks of VOC in the Synthetic Organic Chemicals Manufacturing Industry for which Construction, Reconstruction, or Modification Commenced After January 5, 1981, and on or Before November 7, 2006

- 40 CFR Part 60, Subpart VVa – Standards of Performance for Equipment Leaks of VOC in the Synthetic Organic Chemicals Manufacturing Industry for Which Construction, Reconstruction, or Modification Commenced After November 7, 2006

- 40 CFR Part 60, Subpart KKK – Standards of Performance for Equipment Leaks of VOC From Onshore Natural Gas Processing Plants for Which Construction, Reconstruction, or Modification Commenced After January 20, 1984, and on or Before August 23, 2011

- 40 CFR Part 60, Subpart OOOO – Standards of Performance for Crude Oil and Natural Gas Production, Transmission and Distribution for which Construction, Modification or Reconstruction Commenced After August 23, 2011, and on or before September 18, 2015

- 40 CFR Part 60, Subpart OOOOa – Standards of Performance for Crude Oil and Natural Gas Facilities for which Construction, Modification or Reconstruction Commenced After September 18, 2015

- 40 CFR 63.1363 – Standards for Equipment Leaks

- 40 CFR Part 98, SUbpart W – Petroleum and Natural Gas Systems

- Center for Responsible Shale Development

Canada – British Columbia

- BC Oil & Gas Commission – Flaring and Venting Reduction Guideline

- BC Industrial Facility Greenhouse Gas Emissions

- Western Climate Initiative – Final Essential Requirements for Mandatory Reporting

Canada – Alberta

- Alberta Energy Regulator, Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting/Section 8.6 Fugitive Emissions Management

- Alberta Energy Regulator, Directive 084: Requirements for Hydrocarbon Emission Controls and Gas Conservation in the Peace River Area

Canada – Ontario

- Petroleum Refining – Industry Standard under the Local Air Quality Regulation (O. Reg. 419/05)

- Guideline for Quantification, Reporting and Verification of GHG Emissions

Canada – Saskatchewan

- Saskatchewan Upstream Petroleum Industry Associated Gas Conservation Directive

- Saskatchewan Upstream Flaring and Incineration Requirements

LDAR Tag Durability

Express only produces LDAR tags that are durable enough to withstand the harshest oil & gas environments, with an outdoor lifetime of 30+ years. All LDAR tags withstand the following elements:

- Prolonged exposure to UV radiation

- Extreme temperatures

- Caustic chemicals and solvents

- Repeated abrasion

- Moisture and salt spray

- Multiple freeze/thaw cycles

Barcode Tags for LDAR Compliance

- LDAR Tags in Aluminum or Stainless Steel

- Calibration Tags

- Maintenance Tags

- Pump & Valve Tags

- Equipment, Instrument & Meter Identification

- Connector & Flange Tags

- GHS, Warning & Safety Signs

- Pipe, Hose, Drum, and Inventory Identification

- Instruction, Safety, Warning, and Inspection Labels

- Equipment Signs and Tags

- Warehouse Management Tags

- Asset Management Tags

FEATURES

- 21 Point Inspection Every Order

- Every Barcode Validated for Accuracy

- Complimentary Certificate of Conformance

- ISO 9001 Certified

- Fastest Turnaround Times in Industry

- Streamlined Production

- 24 Hour Rush Expedite Available

- Clean Manufacturing

- Custom Design & Build

- Free Graphic Design Services

- Helpful Customer Service

- Unlimited Proofing & Revisions

- Driving Business Efficiency